- (86)13915349938

- yiru.wang@wxfengwei.com

Welding Rotator

Ideal equipment for

every heavy fabrication need

-

100% lncreased safety

-

Radically shorter workcycle

-

Improved quality

-

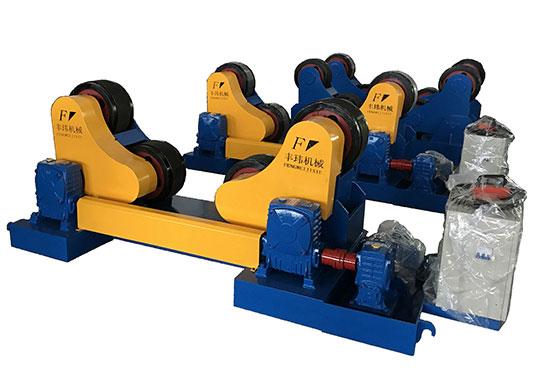

Turning roller

A turning roller refers to a device that drives the cylindrical weldment to rotate by means of the friction between the weldment and the driving roller. The Turning roller series consists of self-adjusting, adjustable, flat car, tiltable, anti-axial movem

Contact Us

-

80T walking welding rotator

The 80T walking welding rotator is developed according to the technical requirements stipulated in JB/T9187-1999 "Welding Rotator".

Contact Us

-

1 Ton Adjustable Welding Rotator

There are two main types of 1 ton adjustable welding rotator, one is conventional welding rotator and the other is screw welding rotator.

Contact Us

-

Pipe Rotator For Welding

FENGWEI pipe rotator is a tool that makes welding pipes and other circular items easier. By integrating two rolling metal pieces, pipe rotator can work with small or huge sizes while saving time.

Contact Us

-

30ton lead screw welding rotator

Lead screw welding rotator is composed of 1 power and 1 idle roller, i.e. 1 set including driver and idler). 30 ton is one of popular lead screw models selected by clients to fabricate cylindrical objects.

Contact Us

-

40 ton self aligning welding rotator

40 ton welding rotator is one of models among Fengwei made self aligning turning rolls. Likewise, the model consists of 1 power and 1 idler, each can load 20 ton of cylindrical objects respectively.

Contact Us

-

Welding Turning Roll

If you are dealing with welding and fabrication work regularly, Pipe Welding Rotator is the best tool for your company to move any cylindrical workpiece for the purpose of welding.

Contact Us

-

10 Ton Welding Rotator

A set of 10 ton welding rotator is composed of 1 power + 1 idler. Each one can load maximum 5 ton respectively.

Contact Us

-

100T self-aligning welding rotator

As a kind of welding rotator, a self-aligning welding rotator plays a vital role in the welding and assembly of workpieces. When facing large objects, it is necessary to prescribe the right medicine and choose a larger configuration welding rotator.

Contact Us

-

Polyurethane Roller

Polyurethane Roller(PU Roller) is used in various industries for its high wear resistance, high bearing capacity, and excellent tear resistance.

Contact Us

-

welding rollers

Welding rollers, also called welding rotators, play an auxiliary role in welding large-scale equipment. There are many types of welding roller racks, including self-adjusting, adjustable, flat-car, tiltable, anti-moving, and explosion-proof.

Contact Us

-

Welding rotator with walking

Mechanism of Welding rotator with walking,Two sets of driving devices are installed on the driving roller. The driving device consists of the motor and reduce.

Contact Us

-

Pipe Welding Rotator

The pipe welding rotator plays a vital role in the automatic production of welding. We have many kinds of pipe welding rotators, the most commonly used are: self-adjusting, explosion-proof, screw, traditional, adjustable, etc.

Contact Us

-

Turning Rolls

Turning rolls, also called welding rotator, is a common welding auxiliary equipment. Among welding automation equipment, turning rolls can be matched with many types of equipment, such as welding positioner and welding manipulator.

Contact Us

-

Pipe Fit Up Turning Rolls

Fit up welding rotator is one of welding auxiliary devices, which has similar but advanced technology comparing to conventional welding rotator. Comparing with conventional welding rotators

Contact Us

If you are dealing with the welding process regularly, welding rotators play an essential part in your welding industry. By using them, you can deal with large cylindrical objects in order to do the welding process effortlessly. They are liable to weld the outer as well as the inner part of the object at ease.

Welding rotators help in rotating the object with the necessary friction between the roller and the welding object to rotate it. For rotation of the object, they contain a base, power driving tool, rollers, and other outer structures. This equipment is the best solution to save time and reduce labor costs, and they can perform even light or heavy-duty tasks quickly and effectively.

There are different types of welding rotators available in the market with a bit different features. If you want to know about them for increasing the productivity of the company, you can find them below:

Fit-up rotator

You can find this fit-up rotator best as it comprises four independent fill-up rollers, and the work of rollers is to lift the process that is supported by the cylinders. Welding Rotator is used to assemble the section pipes such as tank application, wind tower, etc. These are great options to reduce the labor cost and help you to enhance the work performance that leads to your company with an increased conversion ratio.

Pipe Fit Up Turning Rolls

The 20 Tons conventional turning rollers

These conventional rotators are eligible to load the 20 tons loads with a suitable workpiece of 500-3500mm. It contains a rubber wheel of 350*1290 mm along with a metal wheel. You can adjust the distance of the wheel manually with screws or bolts provided with the roller separately. The power of the motor is 2X1.1 KW, and that is the best to handle a large workpiece with minimum effort. Further, these rollers are used in pressure vessels, chemical equipment, oil and gas, and many other workpieces. So, you can adopt them also to give a boost to your overall work performance.

20 Tons conventional turning rollers

The 10 Tons conventional roller

These 10 tons conventional rotators are liable to load the 10 tons of loads efficiently with the suitable workpiece range of 320-2800 mm. The wheel can be easily adjusted by the bolts and screws that are given separately by the company. The overall dimension of this welding rotator is 2440X610X550mm with a net weight of 1.6T. You can use this roller to handle pressure vessels, boiler, chemical tools, storage tanks, and many other workpieces. These are also very suitable for your work if you have a high workload. You can rely on them to work fast and with adequate efficacy.

10 Tons conventional roller

The 60 Tons self-aligned roller

These self-aligned rollers are suitable for large cylindrical objects as they can easily handle 60 tons loads adequately along with a 750-4800mm workpiece. As its name itself says, you can adjust its wheel space via self-alignment. Also, welding rotators are widely used in boilers, chemical tools, oil and gases, shipyards, wind energy, and a lot more other workpieces. These are the best welding rollers for heavy-duty work activities.

60 ton conventional welding rotator

Conventional rotator

These conventional rotators are used in pressure vessels, boilers, and other essential workpieces. It has a variable rotation speed of the rollers from 100 to 1000 mm per minute. The wheels of rollers are covered with heavy and durable rubber that makes this machine more stable and sturdy. In these rotations, you can find the remote control box with a 12 m span that allows the adjustment in the speed of the rollers while on the go. So, with so many good things, rotators are the best option for your industry to reduce your hard work.

Conventional rotator

Pipe rotators for welding

These pipe rotators are specially designed to reduce labor costs by enhancing the overall productivity of your company. In these types of rotators, the welding head is fixed, and the piping spool moves with a particular speed. Thus, you can blindly count on these rotators for easy operation and reliable work performance while handling the workpieces.

Pipe rotators for welding

Self-aligning rotator

You can find the rotators an innovative welding tool as it contains the well-researched advanced technology on which you can mainly handle pipes, containers, boilers, pressure vessels, and many other cylindrical objects smoothly. In addition, welding rollers feature compact structure, small cubage, attractive shape, lightweight, etc. These self-aligned rollers enhance the quality of welding by improving the productivity of the company. Ultimately, you can get them for your industry to boost work performance.

Self-aligning rotator

These are all the welding rotators that can be used in any industry to enhance productivity and lead the company to a better profit ratio. You can find several companies that deal in them, and you can choose any one rotator according to the needs of the company workload.

For this purpose, Fengwei is the best company that provides all types of welding rotators and other equipment necessary for any company to grow with better productivity. In this company, 3200 plus machines are available, and more than 30 countries rely on this company to get their desired roller machines.

welding rotator

Also, the company offers all the machines with innovative technology that are made of the best quality. You can find these tools durable and sturdy that stay with your life.

Conclusion: As we know, rotators contain sturdy rollers that can rotate any cylindrical object in order to weld it perfectly. This Welding Rotator can be used to handle both tasks, whether it is light or heavy-duty. Also, they are used in boilers, containers, and many other cylindrical objects. You can use the rollers to handle large objects with more comfort and ease in order to make your rotating tasks smooth.

You can find many types in them, and you can get any rotator that suits your work profile. Many companies offer them and assure better quality and durability of the equipment. Hence, rollers are the best choice for any fabrication company to increase the productivity of the company so that you can enhance its conversion ratio comfortably.

News

-

2022-05-11

Welding manipulators from China

Read More >>

-

2022-05-11

High-quality welding positioner from China

Read More >>

-

2022-05-11

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

Read More >>

-

2022-05-11

Correct operation of edge milling machine

Read More >>

-

2022-05-11

Beam straightening machine manufacturer from China

Read More >>

-

2022-05-04

The architecture of beam straightener machine

Read More >>

(0510)83695226

yiru.wang@wxfengwei.com

+86-139 1534 9938

(86)13915349938

русский язык

русский язык

EN

EN