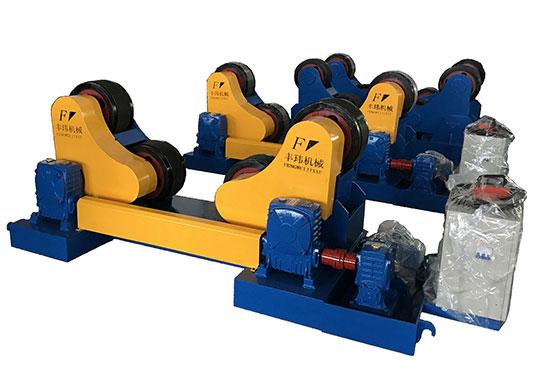

A set of 10 ton welding rotator is composed of 1 power + 1 idler. Each one can load maximum 5 ton respectively. With all robust steel fabricated frame but different roller centering method, 10 ton welding rotator is categorized as 3 models - which are:

Adjustable welding rotator (HGK)

The roller of adjustable welding rotator can be manually positioned by bolts to accommodate tanks with various diameter within the range.

Lead screw welding rotator (HGK)

The roller of lead screw welding rotator can be manually positioned by steering to adjust the distance to accommodate pipes with various diameter. This model suits for light weighted pipes widely.

Self-aligned welding rotator (HGZ)

The distance between rollers of self-aligned welding rotator is self-centered instantly while loading pipes.

All models adopts variable frequency driving system and user friendly but robust mechanical design. With enhanced durability, double reduction worm and wheel gearboxes are adopted. Forklift slots or crane holes are preset with the design for convenience. Please kindly point out if need forklift slots or crane holes.

ASK US

If you are not sure which model suits your request, please inquiry us with following details, we will leave the proposal in your mailbox in 12 hours:

l Max. loading capacity in tons or max. weight of each Tank in tons;

l Total weight of whole pipeline if in production line;

l Manually adjusting roller or self centering welding rotator;

l Minimun and maximium diameter of tank, vessel or cylindrical objects in mm

l Total length of Tank/Vessel in mm

русский язык

русский язык

EN

EN