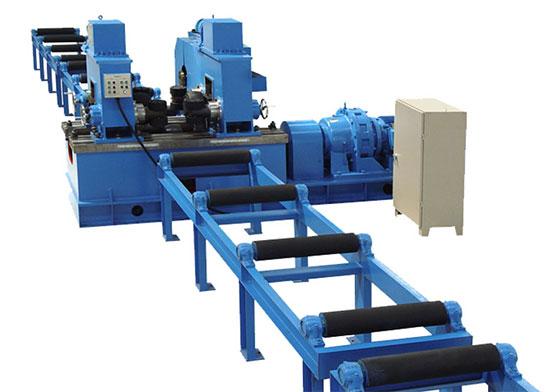

The beam straightening machine is to change the straightness by extruding the bar on the straightening roller. A beam straightening machine is a kind of equipment for straightening pipes, wires, and metal profiles. The main types of beam straightening machines are oblique roll straightening machines, rotary reverse bending straightening machines, pressure straightening machines, and balance roll straightening machines. At the same time, the beam straightening machine also has a two-roll straightening machine, which relies on the angle change of the two rolls to straighten materials with different diameters.

The beam straightening machine is to change the straightness by extruding the bar on the straightening roller. A beam straightening machine is a kind of equipment for straightening pipes, wires, and metal profiles. The main types of beam straightening machines are oblique roll straightening machines, rotary reverse bending straightening machines, pressure straightening machines, and balance roll straightening machines. At the same time, the beam straightening machine also has a two-roll straightening machine, which relies on the angle change of the two rolls to straighten materials with different diameters.

Production operation steps of beam straightening machine

1. First of all, when starting the machine, we have to check whether the transmission box and hydraulic oil of the hydraulic station and the gear oil in the reduction box are full and then start the machine.

2. After checking the working pressure adjustment of the hydraulic system and checking and adjusting the angle of rotation, start the main motor. Then add lubricating oil to each point that needs to be lubricated, so that these operating conditions can be transported flexibly.

3. The staff should wear protective equipment, and must not leave the post or join the post after the machine is turned on. When the oil temperature and oil pressure in the hydraulic station are stable, the upper straightening roller is lifted to the initial position.

4. If the motor stops, be sure to turn off the main power supply, and never change the controller casually.

Adjustment method of beam straightening machine

1. It is not possible to prevent objects on the beam straightening machine to avoid objects falling into the body due to vibration.

2. If the straightening block is not fixed or the protective cover is not covered, we cannot feed the material, nor can the protective cover be opened during operation.

3. After we send the workpiece to the impeller, we must keep the corresponding distance, and the unreliable too close.

4. When straightening the end of the workpiece, our operator must avoid it to prevent it from shaking and hurting people.

5. If the length of the workpiece is less than 2 meters or the diameter exceeds 9 mm, then we must use low speed to operate.

6. After finishing the job, we need to return the straightening block to its original position.

7. When checking the beam straightening machine, we can turn the flywheel by hand, adjust the gap, and wait until everything is normal, we will check if there is any sound in the bearing, and if it is normal, then we can proceed. Operation.

The beam straightening machine produced by Fengwei Machinery has several invention patents and special functions. According to the usage habits of different industries, Fengwei engineers solve the problems of safety, efficiency, and durability of machine use through different solutions. And the beam straightening machine can be well used in the production of the H-beam, Fengwei Machinery provides a complete set of equipment for the H-beam production line.

русский язык

русский язык

EN

EN