The welding positioner allows the manual rotation of the workpieces by bringing them into the desired position. This is useful for the operator for doing smooth work. This equipment has no control system and the engine, but still, it works efficiently. These are mostly used by the welders and provide comfort and a safe working environment. Here in this article, we are going to define this equipment and its benefits.

About welding positioner

The welding positioner performed the rotation in a repeated way once it reached the center of gravity. By using a positioner, you can increase productivity and improve the sales rate. It cut down your time as well as energy. It makes the process of titling & rotating so easy and comfortable.

If we talk about the welding process, then it is equipped with the sequence of the process, and those are, Joining the welding device to the workpiece, controlling the welding process, repositioning the workpiece, and creating a relative motion. So, overall the automated welding is widely popular for controlling and balancing the movement of workpieces & welding heads automatically.

This is used in a plethora of welding processes starting from inert tungsten gas, inert metal gas, and submerged arc welding. The workpieces can be adjusted in the best possible way, but it can only be achieved with the help of welding positioners.

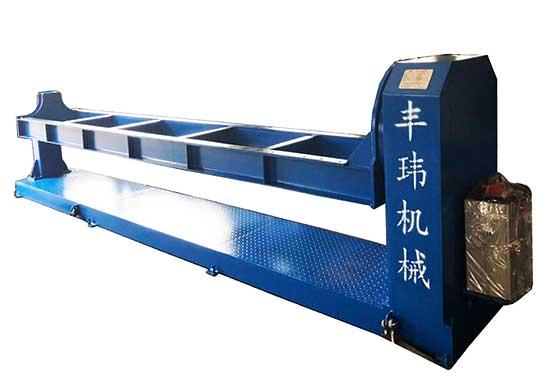

Head And Tail Stock Welding Positioner

How welding positioner helps effectively?

The automated welding positioner is attributed to the automatic welding that is beneficial for improving the economy in a faster period. It provides consistent quality and reduces defects during the welding process. If you are looking for the most consistent portable equipment, then this could be the one and only solution for you. The welding positioners have come in a variety of sizes with varying capacities.

The robust benchtop positioner machines come by holding a plethora of features, including the digital programmable controller. This is helpful to control the rotational angle and also dwelling time. You don't have to make so many efforts because you are just one tap away to do your work.

If you are worried about lifting, rotating, and tilting the workpieces, then here is the solution for you. This device is available in a variety of capacities, shapes & sizes. This is the one-way solution to improve the fabrication and welding process. With the help of them, you can increase consistency. This is widely popular among welders because it is easy to operate features & accessibilities with the integrated equipment. These are used to enhance the operator's ergonomics.

This is specially manufactured by keeping in mind the welder's comfort. It helps to reduce the fatigue of welders. With this, they can stand in one position because the device can rotate to 360 degrees. It has metal fabrication and a CNC machine that easily shapes the metal parts and components. To operate this, you have to adjust the workpiece on the welding positioner.

Benchtop Positioner

What are the benefits of using the weld positioners?

There are huge advantages of using a benchtop positioner,and here are those:

1. Improved quality

When you use a welding positioner, then you get accurate results. It lowers down the chances of error.

2. Worker safety

Designing a welding positioner is specially made for the safety of the worker. This device can rotate up to 360 degrees so that the worker doesn't need to move from their place.

3. Reduce fatigue

This device is designed in such a way so that it allows a worker to stand in one position. A welder can adjust this machine according to your height and level of comfort. It allows them to improve their productivity.

4. Semi-auto functioning

This can be used as a semi-automatic machine after connecting it to a power source. Through this, a welder can increase his speed and productivity.

5. Compact space

You can adjust this device in a compact space, and it will reduce the clutter.

Welding Positioner

Points a welder should know while working with the Weld positioners

1. Determine the center of gravity

You should determine the point where you held the object. When you work with the welding positioner, then it is important to consider the center of gravity by considering where to hold the workpiece. You have to determine the size & weight so that you can balance the weight from all axes. The center of gravity will change when the welder adds extra workpieces having different weights and sizes of the positioner. So, be sure about the COG first.

2. Correct attachment

The way you anchored the workplace onto the welding positioner is a crucial factor. It also depends upon the way you separate the workpiece after the task is done. There is some specific task that needs to be repeated, and it needs unique production fixtures. So, you have to determine the attachment position according to the size and shape of the workpiece.

3. Flat even surface

Make sure that the whole weld positioner's unit is mounted onto a flat and even surface. If it is not set properly, then it may fall off in the middle of the operation that is dangerous. You can also mount the positioner vertically too.

L-shaped welding position

What are the different applications of weld positioners?

The benchtop positioner is basically used for a variety of purposes. These are mainly used in the welding industry and fabricating. Here we point out some major applications of weld positioners:

1. It helps to rotate the parts while assembling.

2. For the rotary positioning.

3. Mounting of welding equipment.

4. It helps to rotate the workpiece with the huge offset loads.

5. This is used for the welding of Shafts, pipes, and wheels.

welding positioner

Conclusion

If you are also looking for a welding positioner for the better productivity of your workers and to make the process of welding and fabrication smooth, then you should have an idea about it.

But before purchasing, a chine makes sure about the authenticity of manufacture and supplier. Purchase this machine from genuine manufactures and suppliers so that it can match your requirements.

русский язык

русский язык

EN

EN