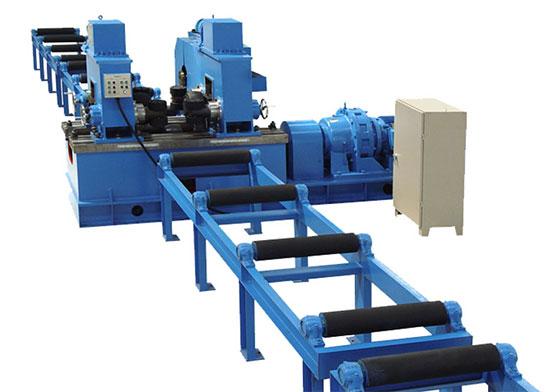

The beam straightening machine changes the straightness by extruding rods, etc. Through straightening rollers. Generally, there are two rows of straightening rollers, and the number varies. There are also two-roll beam straightening machines, which rely on the angle change of the two rolls (concave in the middle, hyperbolic rolls) to straighten materials of different diameters.

The working principle of the beam straightening machine: The position of the rollers is at a certain angle with the direction of movement of the straightened product, two or three large ones are active pressure rollers, which are driven by the motor to rotate in the same direction, and several small rollers on the other side are driven pressure rollers, which are rotated by the friction of a rotating rod or tube. To achieve the required compression of the product by the rollers, these small rollers can be adjusted forward or backward at the same time or separately. Generally, the more the number of rollers, the higher the precision of the product after straightening. After the product is bitten by the roller, it continuously moves linearly or rotationally, so that the product is subjected to various deformations such as compression, bending, and flattening, to achieve the purpose of straightening.

Types: Straightening equipment mainly includes pressure beam straightening machines, balance roll beam straightening machines, rotating reverse bending beam straightening machines, and so on.

Straightening equipment is mainly used in steel, metallurgy, machinery manufacturing, and other industries. In steel rolling machinery, beam straightening machines can be divided into pressure beam straightening machines, roll beam straightening machines, pipe and bar beam straightening machines, and tensile beams according to structural characteristics there are several types of straightening machines, stretch bending beam straightening machines, etc. There are many types of beam straightening machines for plates and strips. According to the product category, roller beam straightening machines can generally be classified as straightening profiles and steel pipes, straightening medium and thick plates, and straightening thin and medium plates. For medium and heavy plate beam straightening machines, the work rolls on the entire row are generally adjusted in parallel. Usually, the two upper work rolls (also called guide rolls) at the entrance and exit are made to be individually adjustable to facilitate the introduction of the rolling stock and improve the quality of the straightening. This straightening machine is widely used to straighten medium and thick plates above 4-12mm.

Adjustment of beam straightening machine

The adjustment of the beam straightening machine mainly includes the axial adjustment of the upper and lower straightening rollers, the pressure adjustment of the lower straightening roller, the pitch adjustment of the straightening roller, and the adjustment of the straightening elevation. The order of adjustment is generally to first adjust the straightening elevation, then adjust the pitch of the straightening rollers, and then adjust the pressure of the lower straightening roller, which is the axial adjustment of the upper and lower straightening rollers. All adjustment parameters in the straightening process are given by the second-level computer system, and the first-level computer plc control system is executed.

A steel feeder (a pair of nip rolls with a diameter of 260mm) is set on the input roller table before the beam straightening machine, which is driven by a hydraulic motor and can rotate, lift, and traverse to align the rolling stock with the rollers of the beam straightening machine. Centerline.

1. Axial adjustment of upper and lower straightening rollers

The upper and lower straightening rollers are electrically adjusted axially to make them align with the sub-l shape, and the adjustment stroke is +40mm. To prevent axial play, a tapered thrust bearing is installed, and the bearing seat is hydraulically locked.

2. The adjustment of the lower straightening roller

The upper roller of the beam straightening machine is fixed in the vertical direction, the lower roller can be adjusted electrically in the vertical direction, the adjustment stroke is 350mm, and the adjustment distance of the upper and lower straightening rollers is 850~1200mm. The adjustment function of the lower roller is to press the upper roller to find the zero position, and the second is to adjust the pressing amount of the roller.

3. Pitch adjustment system

The pitch adjustment system is divided into two parts, the left, and the right, with the no. 5 roller (fixed roller) as the center, two left and right upper rollers and one lower roller constitute two sets of pitch adjustment systems, which are respectively driven by two motors to adjust the roller distance and adjust the stroke. It is 2200 - 1200mm=1000mm.

4. Straightening elevation adjustment system

When straightening different types of h-beams, since the elevation of the roller table before straightening remains unchanged, to keep the section centerline of the steel to be straightened and the straightening center line consistent, the whole frame of the beam straightening machine must be raised and lowered, and the height of the frame must be raised and lowered. The stroke is 300mm.

Quick roll change for beam straightening machine

The loading and unloading of the straightening roller are carried out with a special hydraulic roll changing tool. When the roll is changed, the pressure of the straightening roll and the cone sleeve are respectively relieved. Taper sleeves and straightening rollers are pressurized. The time to replace a complete set of straightening rollers should not exceed 30 minutes.

русский язык

русский язык

EN

EN