Choose the Right Welding Machine

It is a good idea to consider a welding machine as a long-term investment. Buyers should consider all options before making a purchase. The situation will determine which type of welding process is most appropriate and which machine should be used. The most common type of welding is metal arc welding. Before you purchase a welding machine, it is essential to evaluate whether it is the right choice. This is different from plasma cutting welding machines. By melting and fusing two pieces of metal, welding is a way to join them. Plasma cutters are used for metal fabrication. Many people mistakenly believe they can be done together.

Consider the material that you will be welding. Gas metal arc welding is done by feeding a filler wire made of bare metal and shielding it with gas using an electric torch. This creates an "ark", which is the actual welding machine. For most common joint applications, a welder is the best option. Third, think about whether time constraints may affect the process. Each machine has its duty cycle. The welder's duty period is the amount of time it can operate before it must be shut down to cool down. Less expensive welders often have a shorter duty cycle than those of higher price. Some welders are capable of running continuously at 100 percent duty cycles. Based on this, let's discuss more about this in detail.

Advantages of Welding Machine

Last, consider the power and portability of the machine. The machine may be used in a shop, so it will not necessarily need to be portable. A package that is portable and can handle heavy-duty field repairs will be necessary. A generator that is engine-powered and gas-powered may be needed to provide power for welding or auxiliary power in-field repairs.

A benchtop positioner is an excellent product that provides welding assistance for pipe and tube assemblies. The workpiece can be rotated past the welding beam, allowing the welder the freedom to continue welding without being restricted by the positioner. Welding can be trusted as your source for used and new benchtop welding positioners, floor turntables, or other welding equipment. We have the resources and knowledge to supply you with a tabletop weld positioner made to your specifications.

Safety is the most important consideration when operating a benchtop welding positioner, new or old. Before any work can be done on the machine, it should be secured to a stable and flat surface.. It is important to have it connected during welding. Without it, electric parts could be damaged. It is also important to ensure that the positioner can work with the electricity generated by welding. Also, make sure to read the specifications of your welding positioner. The size and speed of the required operation for the welder determine the motor and control. Refer to the specifications to find out if the manufacturer has provided any information.

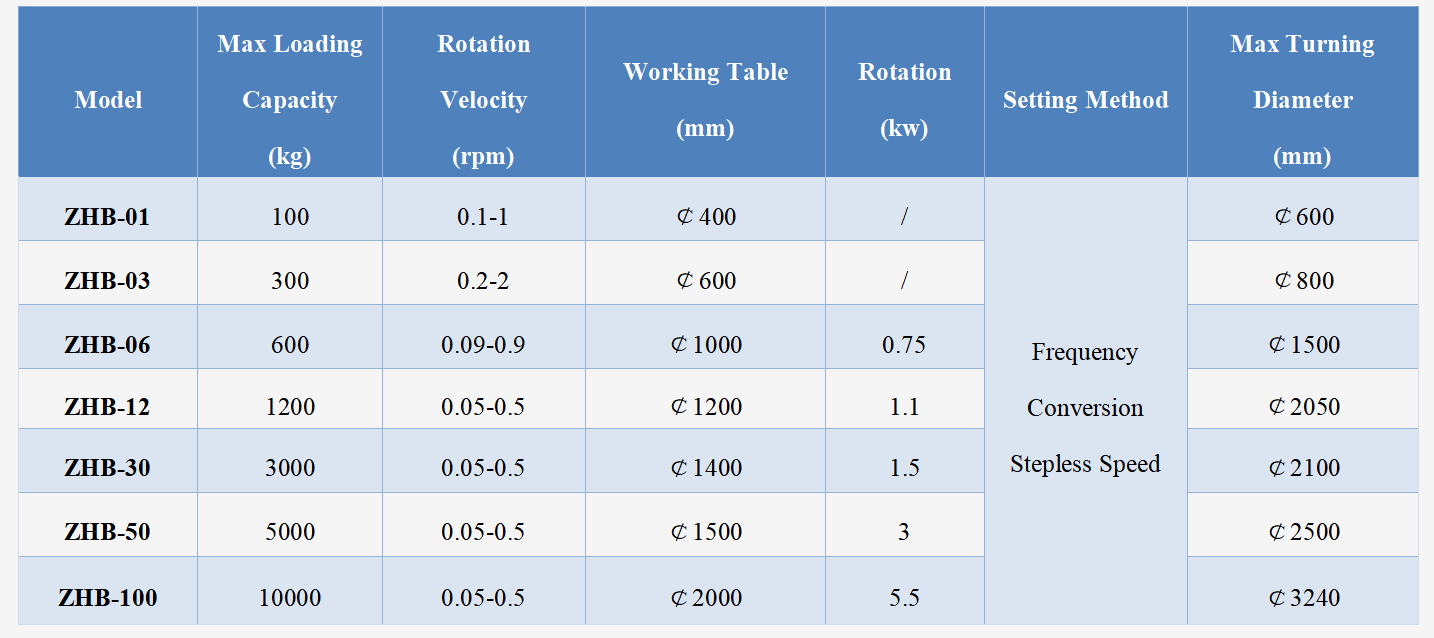

The benchtop positioner offers exceptional workpiece positioning capabilities in a compact frame design that can easily be mounted on a tabletop or workbench. Listed below are some of the technical features and technical aspects of our tabletop weld positioners:

Ø Easy adjustments with electric foot pedal switches

Ø There are many options for positioner sizes

Ø Maximum weight: 330 lbs

Ø Manual tilt

Ø Variable speeds

Welding offers various benchtop and portable welding positioners to meet your needs, whether you need one for your garage or your shop. Welding offers a variety of tabletop welding positioners in various sizes and brands. For complete customization, our service department can add components like foot pedals and remote hand pendants, gripper chucks, outboard support, matching tailstocks, and gripper chucks to your unit.The positioning device uses a seating structure that mainly composes frame, flip device, and rotary device. It also includes electrical control and other parts. The work table rotates at an AC frequency variable speed. This ensures that the work table meets the requirements for the welding speed. The connector connects the positioner to the manipulator.

Welding positioners

This equipment is specialized and is intended primarily to be used for pipe welding and details. Positioners can perform many operations with tube stock as part of their mission. Positioners are capable of performing all types of manual and automatic welding. Many options are available for the devices, including different speeds, load capacities, destinations, and other options.

A welding positioner can be described as a type of position-changing machine. It can turn the weldment over and turn it around so that the weld seam is always in the most accessible welding position. Welders can save time, increase welding quality, and decrease their labor intensity by using welding positioners. It is essential to ensure that the equipment necessary to automate and mechanize the welding process can be used. To create an automated welding center, the welding positioner can be combined with a robot or manipulator.

According to the automatic function, there are several welding positioners: L type, benchtop, benchtop, L-type, single-axis rotary, single column, lifting, double column, and other benchtop positioners. Benchtop positioner has the function of automatically rotating work pieces with rectangular, clone or irregular shapes in 360 degree. It applies to different loads and shapes. If you require more features such as up and down movement or tilt, there are other models of welding positioner for your choice.

How to Choose the Right Welding Positioner

The weight of the welding stationer, the center of gravity, and eccentricity for the weldment over the entire surface must all be within the data range. A specific capacity must also be maintained.

If the optional welding positioner can be used for circular seam welding, the rotation speed must be determined according to the groove. It should not exceed the adjustment range of the positioners rotation speed. Can the whole process be made smooth?

If the overall size of the welding positioner is significant on the outside contour, you will need to consider the angle of the worktable or whether it can achieve the best weldment position. To ensure that the welding process is uninterrupted, the inclined corner should be protected from the weldment.

Once the welder positioner is turned on, attach the electromagnetic fixture and water-cooled equipment.

The welding parts that require a high current to meet the requirements of the welder are needed.

русский язык

русский язык

EN

EN