It is unlikely that you are not aware of what the product mentioned in the title of this article is, and you still clicked on it. We should still take a slight look at what a positioner is and why it is a good product for welders.

An instrument designed to grip and spin an object so that the worker can work on a properly inclined gradient and a uniform plane is called a welding positioner.

The precept of how a weld positioner works is straightforward – it operates by diligently clenching or holding onto the specific object. Then, it tilts and rotates in 360 degree according to the welder's requirements.

welding positioner

WHY SHOULD YOU GET A WELD POSITIONER?

A welding positioner is a helpful tool that many industries (big or small) invest in for welding. Here are a few reasons why:

● Advanced standard: The operation of a weld positioner allows precision; this suggests that there are low possibilities of a worker making a mistake.

● Welder Protection: A weld positioner's design guarantees the workers' protection. That is because the object to be welded is always placed properly in the positioner just, so it would not make any movement while working. Their safety cannot be ensured if the object is simply chained to the positioner as there are chances of out-of-control movements, which can be unsafe.

● Decreased Exhaustion: A welding positioner is constructed in a way that permits an employee to stand in a single position and weld. A positioner can be adjusted according to the worker's convenience. As a result, their tiredness will certainly lower. A positioner would also assist in enhancing productivity.

Main parts of welding positioner

WHAT ARE HEAD AND TAILSTOCK WELDING POSITIONERS?

Welding is done in several industrial processes. The workpiece one needs to work on can be of any shape and form. While some objects are simple and easier to handle with the help of a typical positioner, some require a particular kind of positioner.

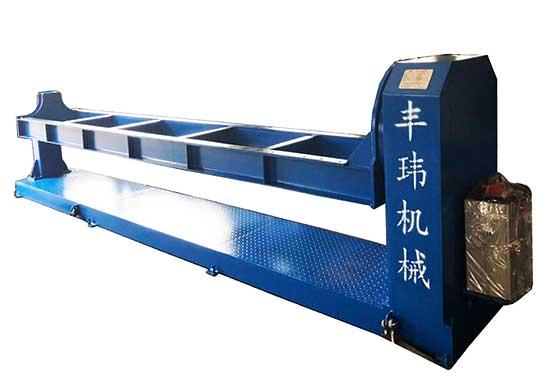

A Head and tail stock welding positioner is exerted usually for long squares or quadrilaterals that require some support from each of its ends. A regular alignment of such positioners comprises a compelled headstock positioner with a stable tailstock. Most wagon or carbody industries are in big favour of head and tail stock welding positioner.

Head and tail stock welding positioner

SOME CHARACTERISTIC FEATURES OF HEAD AND TAILSTOCK POSITIONERS THAT MAKE THEM A GOOD CHOICE

● They are used for the welding of long and rectangular objects.

● They come with easy maintenance and are of great use.

● If you buy a positioner worth its while, it usually offers significant capacities.

● They come in different models for different requirements. Many companies even offer customized services.

● Most positioners do not require any maintenance in the grounding system.

WHAT TO NOTICE WHILE USING A WELD POSITIONER?

A device that is as useful as a weld positioner must be used only with the proper knowledge of its functioning and operation only. There are a few key features that every user must keep an eye on, and pay attention to little details when using a weld positioner for their industries.

You must pay attention to these points before using a positioner:

● Thinking about the part where the mass of the workpiece is held (Centre of Gravity):

After choosing the positioning weld, you must consider the center of gravity of the object in addition to its length and mass. Due to this, the balance of the object is the same on all its points. This additionally establishes the velocity of spinning of the table. The Centre of Gravity will vary if the worker adds components of assorted masses and sizes to the welding positioner.

● Accurate fitting of the object you're working on:

The manner with which the item you're working on is placed on the welding positioner is an essential aspect because that is often how it might separate once the task is finished. Some precise jobs which one needs to perform recurrently, to be able to supply components for quintessential uses need unique manufacturing furnishings. Apart from this, generally for circular objects, a chuck containing three jaws is used for fixing it onto the positioner. Some items are supposed to be bolted. The way of fixing varies for workpieces of different shapes and sizes. These details ought to be looked upon according to them.

● Leveled uniform floor:

Make sure that the entire unit of the welding positioner is fixed on an even and uniform plane. Otherwise, the object you are working on might lose balance, which might be problematic and hazardous. You can only place the positioner upright onto a surface of any kind if it is secured or chained correctly.

benchtop positioner

benchtop positioner

WELD POSITIONERS APPLICATIONS

Several industries employ weld positioners for their welding tasks and prefer them over any other devices. State below is a few of the applications of these positioners.

● The basic rotation of the object.

● Revolving different components so that they can be fabricated together.

● Many types of items can be welded easily with the help of a positioner.

● Items that weigh extensively can also be rotated and welded through these positioners.

If the work in your industry concerns welding and you are still dwelling on the traditional equipment or manual labor for welding purposes, it is about time you change that. You can work quicker and much more efficiently with the help of a welding positioner.

Various companies sell positioners nowadays, many of which offer extraordinary services and affordable prices. If you want to buy a positioner, you must possess knowledge about their working and other features. Even though this article is attempting to provide you with the correct information, you should research thoroughly both about the device and the company you are considering buying it through.

This way, you will invest in good and the right equipment for you. It will also refrain from any future problems that might come up if you are aware of the proper functioning and working of the device. Make not only the right but also the intelligent decision and work efficiently.

русский язык

русский язык

EN

EN