We have many kinds of pipe welding rotators, the most commonly used are: self-adjusting, explosion-proof, screw, traditional, adjustable, etc. We mainly put the welding workpiece in the V-shaped groove, and according to the welding The size and diameter of the workpiece, adjust the position of the pipe welding rotator to prevent the welding workpiece from separating from it due to improper operation during the welding process, resulting in unimaginable consequences.

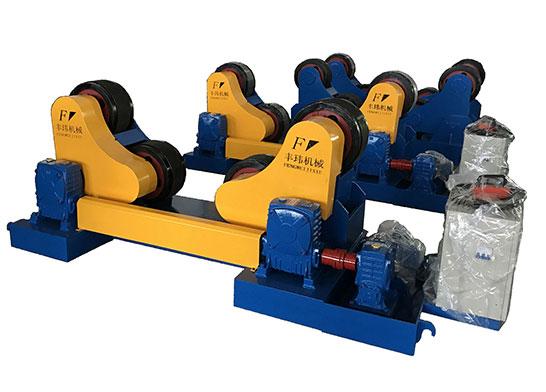

pipe welding rotator

pipe welding rotator

Choose the right pipe welding rotator

Choosing the right pipe welding rotator can greatly increase the productivity of the factory. The factory chooses mainly from the following aspects:

1. The center of gravity and size of the welding workpiece

For anyone who chooses a machine, the first consideration is the size and center of gravity of the welding workpiece. Due to the difference in the center of gravity and size, the load of the selected machine also needs to be adjusted. To know the distance between the center of gravity and the positioning equipment, it must be designed according to the welding workpiece. Position and each welding workpiece need to have an equal balance point on the welding rotator to prevent the workpiece from falling off during the welding process. If the factory is not very clear about its own needs, you can seek a high-quality manufacturer, they have a complete technical team, one-to-one or many-to-one to help customers solve problems.

special pipe welding rotator

2. Selection of welding automation equipment manufacturers

Choosing a high-quality manufacturer can not worry about the use effect of the machine at all, and can provide unexpected help to the factory during the use process. These aspects mainly exist in whether a company’s after-sales and pre-sales services have a complete system, and With a reputation in the entire industry, Fengwei, as an old brand manufacturer established for more than 20 years, not only has high-quality machines but also has been recognized by partners from 22 countries around the world in terms of after-sales and pre-sales services.

Large pipe welding rotator

3. The price of welding rotator

The price of a pipe welding rotator has always been one of the key points that many partners care about. However, the price should be considered from several aspects, such as the quality of the machine, the equipment spare consumables, the content of after-sales and pre-sale services, the form of shipping, and the In terms of cargo cycle, Fengwei is the leader in these aspects. Not only do we have low-cost shipping, but also the delivery speed is one of the best in the industry. In terms of after-sales and pre-sales, we have been recognized by many partners, so if you have Demanded, you can communicate with our engineers, let us achieve a win-win situation together.

русский язык

русский язык

EN

EN