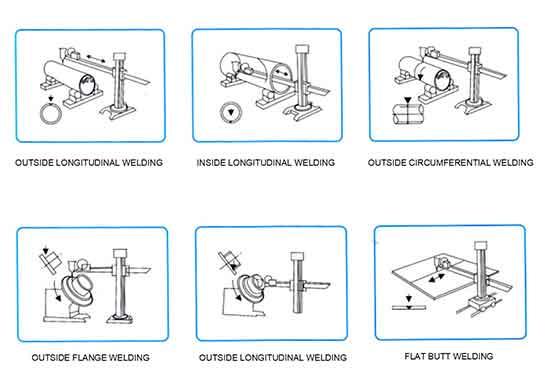

At present, there are various forms of welding manipulators on the market, and there are many differences in their functions, but in general, they can complete the welding functions of several welding positions of plates and tubes.

Simple welding manipulator, including the base, the base is provided with a rotating plate, rotating plate set through-hole, the base ring is provided with a plurality of positioning holes corresponding to the positioning through a hole, positioning pin rod through the positioning hole and positioning hole so that the rotation plate and the base fixed connection; The rotary plate is fixedly connected with the column, the column is provided with a horizontal bracket and a horizontal operation machine, and a 45° tilt bracket is arranged on one side of the horizontal bracket, and a plurality of limit holes are arranged on the tilt bracket, and the limit pin rod passes through the limit hole.

In actual use, the round pipe welding parts are directly set on the inclined bracket, flat butt, fillet weld butt, t-joint butt, can be directly spot welding on the horizontal bracket; In the application, it is found that the welding operation frame can not rotate, it is not convenient to use, and there is no operation platform, welding parts and tools have no place, and the round pipe welding parts are directly set on the inclined bracket, the length of the inclined bracket is fixed, not suitable for the use of different lengths of the round pipe.

Welding manipulator is mainly composed of a base, column, arm, arms lifting mechanism, arm, shrink mechanism, and so on.

1, column and arm are rectangular aluminum alloy beam, double-track type; After welding the column and the transverse arm, the stress is removed, and then mechanical finishing is carried out to ensure higher accuracy.

2, guide seat up and down, around the pulley seat, pulley seat adopts eccentric shaft structure, in order to adjust the gap of the guide rail, compensation guide wear.

3, all shaft parts (including shaft pin) are tempered, gear and moving parts are surface hardening treatment

4. The top of the column is provided with a lifting hole for lifting.

5, horizontal arm vertical lifting drive is through the motor, reducer through the chain and counterweight to achieve the lifting of the arm, and with anti-drop locking device, to prevent chain fracture caused by safety accidents. Limit switches are arranged in the upper and lower limit positions of the column.

6. Horizontal expansion of the transverse arm is realized by the motor driving the rack and pinion through the worm gear and worm reducer. The limit position of the transverse arm is provided with a limit switch, and the speed is regulated by frequency conversion.

7, in the front end of the arm, is also provided with welding gun adjustment mechanism, can realize the welding gun up and down, left and right cross adjustment

8. The control system is mainly composed of the electric control box and remote control box.

External power supply voltage: 380V 50Hz 3P

This electrical system integrates the control of the manipulator and welding power supply. According to the work needs to achieve the control of each equipment.

The electric control cabinet mainly controls each motor on and off, realizes each part action, and carries on the necessary protection to the motor. In addition to the boom telescopic motor control, speed regulation, and protection; The roller rack is reserved for speed regulation and protection.

There are transverse arm speed adjustment, power indicator, power switch button, transverse arm lifting button, inverter alarm indicator, and alarm clearing button on the panel of the electric control cabinet.

The operation panel of the remote control box is equipped with a power indicator light, horizontal arm expansion switch, welding start, welding stop button, and other components, which can remotely complete the main action of each part of the equipment, and control the start and stop of welding.

Through the electric control box and remote control box, each mechanism of the equipment can be operated separately, and various parameters can be manually adjusted according to the situation.

русский язык

русский язык

EN

EN