During the welding process, the active tracking system in the welding rotator will directly affect the positioning of the molten pool; and the incoordination of the transmission devices of the equipment will cause the welding project to be unstable or stop.

Welding process improvement is based on process planning requirements. Active welding has stricter requirements for weldment grooves, pressure vessel environment, and data. We analyze the causes of welding problems that appear and conduct management, verification, and adjustments one by one. The gas maintenance welding of the inner ring seam conducts experiments on various process parameters, studies, and determines the parameter habit values to match each other, especially the control of the welding gun orientation. Through the TV monitoring system and the 0, 1, and 2 axis slides in the three-dimensional electric cross plate, the welding torch position can be adjusted at any time according to the welding conditions to ensure the stability of the welding process.

It is determined by experiment to maintain the gas mixture ratio. In addition to blocking the air and protecting the high-temperature welding zone from air damage, the maintenance gas also affects or determines the shape and process characteristics of the arc to a certain extent, as well as the metallurgical characteristics of the weld. According to the workpiece steel type, plate thickness, welding seam spatial orientation, welding joint quality requirements, welding productivity, and reasonable maintenance gas mixture ratio, it can ensure excellent welding seam formation and avoid spattering. We determined a reasonable range based on the different effects of carbon dioxide and argon in the welding process and verified through experiments when the ratio is good, the quality is good.

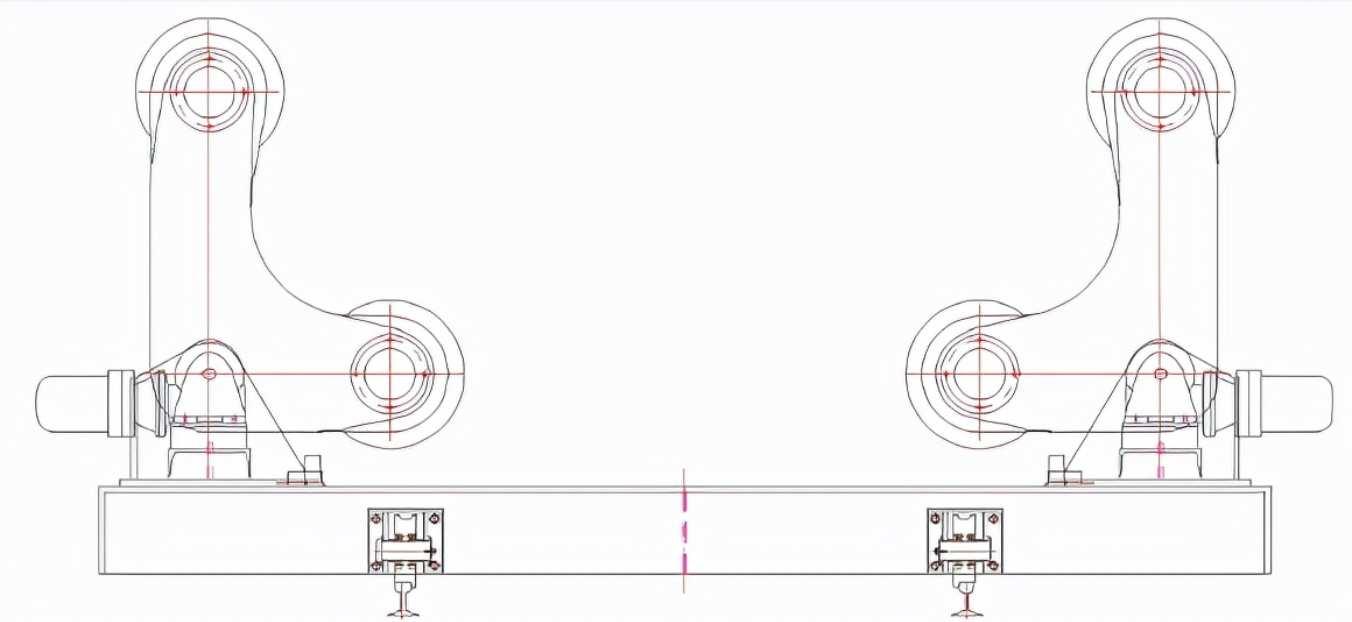

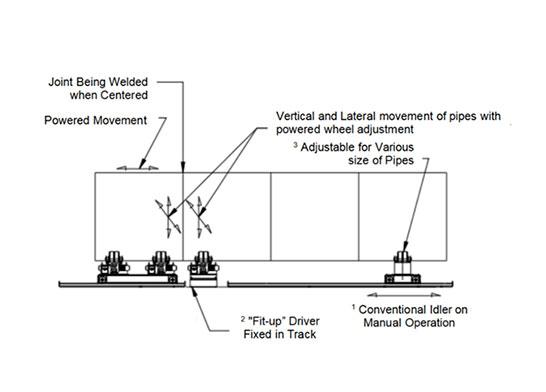

Regarding the welding rotator, the rollers and weldments are round, and all the rollers are of the same length and the axes are parallel. Then the effect of the active sprocket weldment is the force on the welding, and it is also the reaction force of the tumbling sprocket on the weldment, which is what everyone calls the circumferential force. In other words, if the weldment rotates around the axis, its axis will not go up and down.

If a part of the welding rotator is seriously damaged, for example, the time and time of the welding rotator is a bit wrong, the shape of the weldment is different or irregular, then the front and rear rollers will be very different. If it is high or low, the axis of the roller and the axis of the weldment are not parallel. In this way, the touch of the driving sprocket and the driven sprocket of the weldment will cause the shaft to move up and down.

If the number of rollers deflected from the same viewpoint is large, the up and down movement of the weldment shaft will become faster and faster. In addition, if the left and right sides of the weldment are focused, the speed of the shaft will also change. If the axis of the welding rotator is on the same plane, the interval between the rollers does not affect the speed of the shaft moving up and down. Therefore, if there is a slight error in the time and division of the welding rotator device, it is not acceptable.

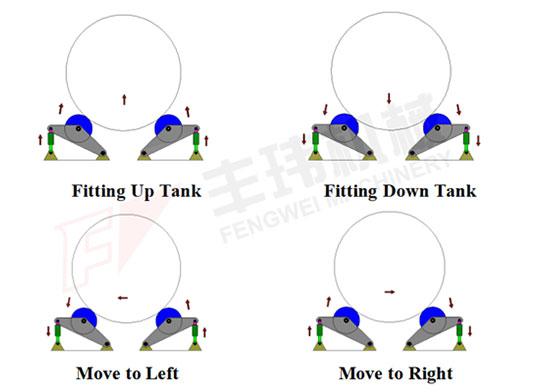

Sometimes there will be axial movement during the operation of the welding rotator, which means that the welding itself has spiral-related motion, then firstly transform the left rotation of the welding rotator into the right rotation operation, and vice versa. The same right rotation is transformed into a left rotation until the weldment no longer exhibits a spiral movement. Be careful when changing. There are several types of organizations that can perform the above transformations. One is the jacking structure. The first step of this structure is to move the rollers up and down so that the weldment will undergo axial changes in its weight. The deviation is the most important thing during operation The intention is to make the welding rotator offset along the middle line, so the translation is a straight horizontal movement along the axis of the weldment.

русский язык

русский язык

EN

EN