Welding Turning rollers are often used to weld the inner and outer girth welds and inner and outer longitudinal welds of some cylinders. It consists of a base, a driving wheel, a driven wheel, a bracket, and a driving device. It can be used in combination with welding positioner and welding operation frame to realize automatic welding production line, which greatly reduces labor intensity and improves production efficiency.

Product features of Turning rollers

1. It can be combined arbitrarily according to the weight and length of the weldment, which is convenient and flexible to use;

2. Automatically adjust the center distance of the rollers within the specified range, suitable for welding parts of different diameters, and the cylindrical body welding parts are placed stably;

3. Driven by thyristor-powered DC motor, stepless speed regulation, large welding speed range, and stable speed;

4. Strong applicability and wide use;

5. Combined roller, the steel wheel is covered with rubber, the transmission is stable, the friction force is large, and the service life is long;

6. Small wheel pressure on the workpiece can avoid cold work hardening on the working surface.

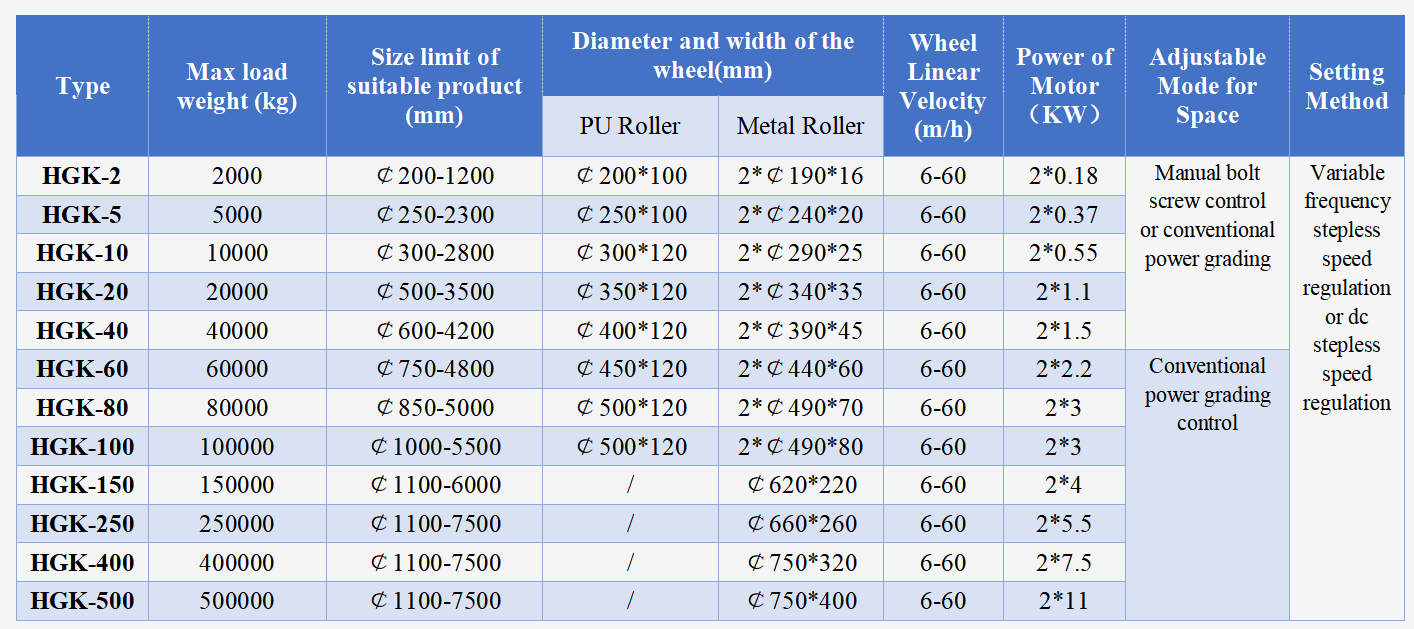

Typle of turning roller

|

Lead Screw Welding Rotator |

Anti-Explosion Welding Rotator |

Self Aligning Turning Rolls |

|

Lead screw welding rotator is one of the invention patents made by Fengwei Machinery, mainly used to meet client’s request of welding small cylinders and avoid damaging the motor, reducer, and electric control box. |

Welding rotator with explosion-proof features, as its name suggests, is a special welding rotator designed with explosion-proof device. It is also one of popular welding automations. |

Self aligned turning rolls are mainly composed of: base, driving rollers (aka driver), idle rollers (aka idler), driving mechanism, and control system, which is ready to use once delivered, with no installation required. |

Conventional Welding Rotator Conventional Welding Rotator |

Welding rotator with walking |

Polyurethane Roller Polyurethane Roller |

| Conventional welding rotator is mainly suitable for the production process of welding rotating bodies such as pipes, pipes, tanks, containers, wind towers, etc. The welding roller bed includes a drive rotator, an idler rotator, a control cabinet, and a wireless suspension controller. | The welding rotator is widely used in boiler, pressure vessel, petroleum, chemical industry, machinery, and other manufacturing industries. welding rotator is used to assist automatically welding inner and outer longitudinal or circumferential seams of cylindrical vessels. | Polyurethane Roller(PU Roller) is used in various industries for its high wear resistance, high bearing capacity, and excellent tear resistance. Equipped with our welding rotator, imported polyurethane material is officially used to coat the roller. |

русский язык

русский язык

EN

EN