Welding turning rolls have very strong advantages for the welding of pipes. Many large metal workpieces are also inseparable from the pipe rotator in welding, polishing, painting, assembly, etc. There are many types of pipeline rotators: self-aligning rotator, adjustable rotator, anti-channeling explosion-proof type, etc. All types of pipeline rotators use the friction between the welding workpiece and the driving wheel to make the welding workpiece achieve the corresponding welding Location.

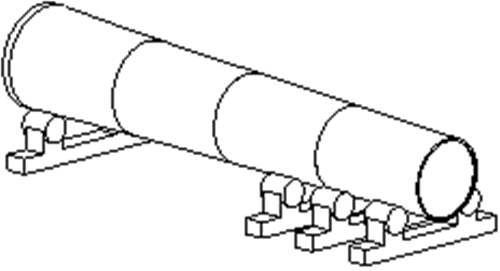

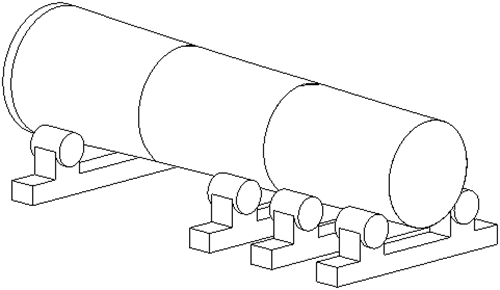

The Pipe rotator is composed of a base, an active roller, a driven roller, a bracket, a transmission device, and a power device drive. The Pipe rotator that is often seen in the market is mainly these standard configurations. It is used in combination with a driving wheel and a driven wheel. However, there are irregularities in many welding workpieces, especially some super-large workpieces. A driven wheelset is used in combination.

Various types of Pipe rotator

self-adjusting rotator

The self-adjusting rotator is very suitable for the welding of pipes. According to the size of the pipe cylinder, the self-adjusting pipe rotator can be adjusted freely. The function of the self-adjusting rotator is very powerful, and it can be well combined with other welding equipment, especially when combined with the welding operation frame, it can well realize the inner and outer longitudinal seam and inner and outer circumferential seam welding of the workpiece.

Adjustable rotator

The adjustable rotator can be used for many types of welding processes. For example, it can well meet the needs of various welding such as manual welding, automatic surfacing, and automatic submerged arc welding, and can also meet the needs of various workpieces. For riveting, there are two types of adjustable rotators, one is a screw adjustable welding rotator, and the other is a machine-adjusted welding rotator. It can adjust the center distance of the rollers to meet the needs of various cylinders. Body welding and assembly.

Anti-channeling explosion-proof rotator

The adjustable roller frame can be upgraded to a lifting type by upgrading the driven wheel, so as to achieve anti-channeling and explosion-proof. The emergence of an anti-channeling explosion-proof rotator can well meet the horizontal position welding of the inner and outer circumferential seams and the inner and outer longitudinal seams of the workpiece. And it can also improve the overall welding quality and bring the welding efficiency to a certain standard.

Maintenance of Pipe Rotators

1. Pipe rotator must check and clear the obstacles on the machine before use.

2. The pipe rotator needs to be placed away from fire and inflammable to avoid accidents.

3. All transmission parts must be lubricated first, otherwise, it is strictly prohibited to use.

4. Pipe rotators that have not been used for a long time must be re-lubricated.

5. The position must be placed in a horizontal position to avoid the accident of the workpiece slipping off during welding, causing human-machine damage.

6. Each component needs regular maintenance and management.

русский язык

русский язык

EN

EN